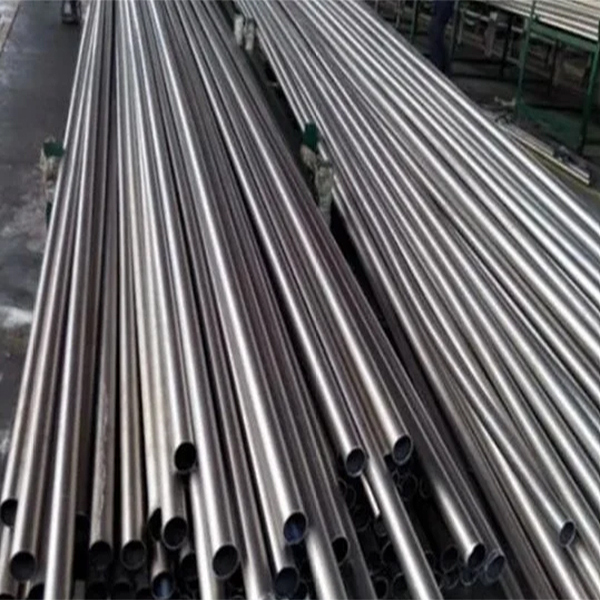

Titanium alloy TA1 tube le ṣee lo i

Titanium Alloy TA1 Tube O jẹ ti titanium alloy, eyiti o le pin si awọn oriṣi mẹta ni ibamu si eto naa.(1 Aluminiomu ati tin ti wa ni afikun si titanium. Aluminiomu, chromium, molybdenum, vanadium ati awọn eroja alloying miiran ti wa ni afikun si titanium. welded ni orisirisi awọn fọọmu, alurinmorin isẹpo agbara le de ọdọ 90% ti awọn agbara ti awọn matrix irin, ati ki o dara machinability.Titanium tube ni o ni ga ipata resistance si kiloraidi, sulfide ati amonia.Idena ipata ti titanium ni omi okun jẹ ti o ga ju ti aluminiomu alloy, irin alagbara ati ipilẹ nickel alloy.Titanium tun ni agbara ipa omi ti o lagbara.

Titanium Alloy TA1 Tube, The Ti o yẹ Standard

GB/T 3620.1-2016 Titanium ati titanium alloy grades ati kemikali tiwqn

GB/T 3624-2010 Titanium ati titanium alloy tube boṣewa

Titanium ati titanium alloy tubes fun ooru exchangers ati condensers

TA1, TA2 ati TA3 jẹ titanium mimọ ile-iṣẹ, eyiti o ni awọn ohun-ini ẹrọ ti o ga, awọn ohun-ini stamping ti o dara julọ, ati pe o le ṣe welded ni awọn fọọmu pupọ.Agbara apapọ welded le de ọdọ 90% ti agbara ti irin matrix, ati iṣẹ gige jẹ dara.Titanium tube ni o ni ga ipata resistance si kiloraidi, sulfide ati amonia.Idena ipata ti titanium ni omi okun jẹ ti o ga ju ti aluminiomu alloy, irin alagbara ati ipilẹ nickel alloy.Titanium tun ni agbara ipa omi ti o lagbara.

Ti a lo ninu iṣelọpọ awọn tubes condenser ni omi okun ti a ti doti, omi pẹlu akoonu ti o ga ti daduro, ati ni awọn iwọn sisan ti o ga.

Titanium Alloy TA1 Tube, Classification

Ni ibamu si awọn histological

1. aluminiomu ati awọn eroja tin ti wa ni afikun si titanium.

2. awọn eroja alloy gẹgẹbi aluminiomu, chromium, molybdenum ati vanadium ti wa ni afikun si titanium.

3. aluminiomu ati vanadium ti wa ni afikun si titanium.

Titanium alloy ni agbara giga ati iwuwo kekere, awọn ohun-ini ẹrọ ti o dara, lile ti o dara ati idena ipata.Ni afikun: iṣẹ ṣiṣe ilana alloy titanium ko dara, gige ti o nira.Ninu sisẹ gbigbona, o rọrun pupọ lati fa awọn idoti bii hydrogen, oxygen, nitrogen ati erogba.Nibẹ ni o wa ko dara yiya resistance, eka gbóògì ilana.

Ti pin nipasẹ awọn eroja ti o dapọ

Ohun alloy ti o da lori titanium pẹlu awọn eroja miiran ti a ṣafikun.Iṣelọpọ ile-iṣẹ ti titanium bẹrẹ ni ọdun 1948. Awọn iwulo idagbasoke ti ile-iṣẹ ọkọ ofurufu jẹ ki ile-iṣẹ titanium dagbasoke ni iwọn idagba lododun ti iwọn 8%.Ijadejade lododun ti awọn ohun elo iṣelọpọ alloy titanium ti de diẹ sii ju awọn toonu 40,000, o fẹrẹ to awọn iru 30 ti alloy titanium.Awọn alloy titanium ti o gbajumo julọ ni Ti-6Al-4V(TC4), Ti-5Al-2.5Sn (TA7) ati titanium mimọ ile-iṣẹ (TA1, TA2 ati TA3).

Ni ibamu si IwUlO ogorun

Titanium alloy le ti wa ni pin si ooru sooro alloy, ga agbara alloy, ipata sooro alloy (ti-molybdenum, ti-Palladium alloy, bbl), kekere otutu alloy ati pataki alloy iṣẹ (ti-irin hydrogen ipamọ ohun elo ati ki o ti-nickel iranti). alloy), bbl Awọn akopọ ati awọn ohun-ini ti awọn alloy aṣoju jẹ afihan ninu tabili.

Titanium Alloy TA1 Tube, Lo

Titanium Alloy TA1 Tube, Ni akọkọ ti a lo fun iṣelọpọ ti awọn ẹya ẹrọ compressor engine ọkọ ofurufu, atẹle nipasẹ awọn apata, awọn misaili ati awọn ẹya igbekalẹ ọkọ ofurufu iyara giga.Ni aarin awọn ọdun 1960, titanium ati awọn ohun elo rẹ ni a ti lo ni ile-iṣẹ gbogbogbo lati ṣe awọn amọna fun ile-iṣẹ elekitirolisisi, awọn condensers fun awọn ibudo agbara, awọn igbona fun isọdọtun epo ati isọdọtun omi okun, ati awọn ẹrọ iṣakoso idoti.Titanium ati awọn alloy rẹ ti di iru awọn ohun elo igbekalẹ ipata.Ni afikun, o tun lo lati gbejade awọn ohun elo ipamọ hydrogen ati awọn ohun elo iranti apẹrẹ.

Orile-ede China bẹrẹ lati ṣe iwadi titanium ati awọn ohun elo titanium ni ọdun 1956. Ni arin awọn ọdun 1960, awọn ohun elo titanium jẹ iṣelọpọ ati idagbasoke sinu TB2 alloy.

Kemikali Tiwqn

| Ipele | N | C | H | Fe | THE | Al | IN | O dara | Mo | In | Of | Agbara Fifẹ (MPa) | Agbara ikore (MPa) | Ilọsiwaju(%) |

| Gr1 | 0.03 | 0.08 | 0.015 | 0.2 | 0.18 | / | / | / | / | / | Bal | 240 | 138 | mẹrin-le-logun |

| Gr2 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | / | / | Bal | 345 | 275 | 20 |

| Gr3 | 0.05 | 0.08 | 0.015 | 0.3 | 0.35 | / | / | / | / | / | Bal | 450 | 380 | 18 |

| Gr4 | 0.05 | 0.08 | 0.015 | 0.5 | 0.4 | / | / | / | / | / | 550 | 483 | 15 | |

| Gr5 | 0.05 | 0.08 | 0.015 | 0.4 | 0.2 | 5.5-6.75 | 3.5-4.5 | / | / | / | Bal | 895 | 828 | 10 |

| Gr7 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | 0.12-0.25 | / | / | Bal | 345 | 275 | 20 |

| Gr9 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 | 2.5-3.5 | 2.0-3.0 | / | / | / | Bal | 620 | 70 | 15 |

| Gr12 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | 02-0.4 | 0.6-0.9 | Bal | 438 | 345 | 18 |

| Iru | A tun le pese TB3, TB6, TC4, TC6, TC11, TC17,TC18 gẹgẹbi awọn ibeere rẹ. | |||||||||||||

| Standard | ASTM B348, ASTM F67, ASTM F136, ISO5832-2, ISO5832-3, AMS 4928, AMS 4930, ASTM F1295, ASTM F1713, MIL-T-9047 | |||||||||||||

| Ohun elo | Metallurgy, Electronics, medical, chemical, petroleum, pharmaceutical, aerospace, etc. | |||||||||||||

Ifihan ọja