TC2 Titanium Alloy Aheet Awo

TC2 Titanium Alloy Aheet Plate, alloy ti o da lori titanium pẹlu awọn eroja miiran ti a ṣafikun.Awọn iru awọn kirisita isokan meji lo wa ni titanium: α titanium pẹlu ipon hexagonal ipon wa ni isalẹ 882℃, ati β titanium pẹlu cube aarin ara jẹ loke 882℃.

Awọn ibeere imọ-ẹrọ:

1. Ipilẹ kemikali ti titanium ati titanium alloy awo yoo ni ibamu pẹlu awọn ipese ti GB/T 3620.

2. Ninu ọran ti atunyẹwo, iyapa ti o gba laaye ti akopọ kemikali yoo ni ibamu pẹlu awọn ipese GB/T 3620.

a.Iyapa iyọọda ti sisanra ti awo naa yẹ ki o ni ibamu pẹlu awọn ipese ti Tabili 1.

b.Iyapa ti a gba laaye ti iwọn awo ati ipari yẹ ki o wa ni ibamu pẹlu awọn ipese ti Tabili 2.

c.awọn igun ti awo yẹ ki o ge si awọn igun ọtun bi o ti ṣee ṣe.Iyapa ko yẹ ki o kọja ipari ati iwọn ti dì

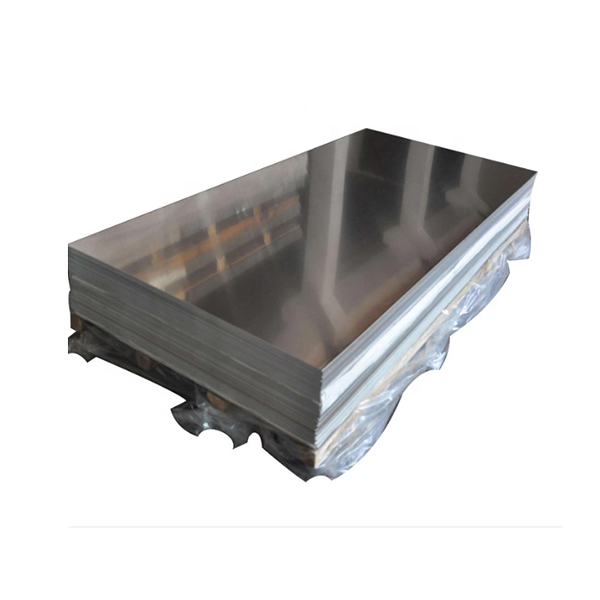

TC2 Titanium Alloy Aheet Plate, The Production Specification

T 0.5-1.0mm × W1000mm × L 2000-3500mm

T 1.0-5.0mm × W1000-1500mm × L 2000-3500mm

T 5.0- 30mm × W1000-2500mm × L 3000-6000mm

T 30- 80mm × W1000mm × L 2000mm

TC2 Titanium Alloy Aheet Plate, Ipo iṣelọpọ

Ipo iṣẹ gbigbona (R) Ipo iṣẹ tutu (Y) Ipinle Annealing (M)

TC2 Titanium Alloy Aheet Awo, Reference Standard

1: GB 228 Irin fifẹ igbeyewo ọna

2: GB/T 3620.1 Titanium ati titanium alloy onipò ati kemikali tiwqn

3: GB/T3620.2 Titanium ati titanium alloy ni ilọsiwaju awọn ọja kemikali tiwqn ati tiwqn Allowable iyapa

4: GB 4698 Ọna oju omi okun fun iṣiro kemikali ti titanium, titanium ati ferroalloys

TC2 Titanium Alloy Aheet Plate, Awọn ibeere Imọ-ẹrọ

1: Ipilẹ kemikali ti titanium ati titanium alloy awo yoo ni ibamu pẹlu awọn ipese ti GB / T 3620.1.Ninu ọran ti atunyẹwo, iyapa ti o gba laaye ti akopọ kemikali yoo ni ibamu pẹlu awọn ipese GB/T 3620.2.

2: Iyapa iyọọda ti sisanra ti awo naa yẹ ki o ni ibamu pẹlu awọn ipese ti Tabili 1.

3: Iyapa ti a gba laaye ti iwọn awo ati ipari yẹ ki o ni ibamu pẹlu awọn ipese ti Tabili 2.

4: Awọn igun ti awo naa yẹ ki o ge si awọn igun ọtun bi o ti ṣee ṣe.Iyapa ko yẹ ki o kọja ipari ati iwọn ti dì

Alloying

TC2 Titanium Alloy Aheet Plate, alloy ti o da lori titanium pẹlu awọn eroja miiran ti a ṣafikun.Awọn iru awọn kirisita isokan meji lo wa ni titanium: α titanium pẹlu ipon hexagonal ipon wa ni isalẹ 882℃, ati β titanium pẹlu cube aarin ara jẹ loke 882℃.

(1) Awọn eroja alloying le pin si awọn ẹka mẹta ni ibamu si ipa wọn lori iwọn otutu iyipada alakoso:

Awọn eroja α-iduroṣinṣin, gẹgẹbi aluminiomu, erogba, atẹgun ati nitrogen, ṣe idaduro ipele α ati mu iwọn otutu iyipada alakoso.Aluminiomu jẹ ipin alloying akọkọ ti alloy titanium, eyiti o ni ipa ti o han gbangba lori imudara agbara alloy ni iwọn otutu yara ati iwọn otutu giga, dinku walẹ kan pato ati jijẹ modulus rirọ.

(2) β-stable eroja le ti wa ni pin si meji orisi: isocrystalline ati eutectoid.Awọn ọja ṣe ti titanium alloy

Awọn tele ni molybdenum, niobium, vanadium ati be be lo;Awọn igbehin ni chromium, manganese, Ejò, irin, silikoni ati be be lo.

(3) Awọn eroja ti o ni ipa diẹ lori iwọn otutu iyipada alakoso jẹ awọn eroja didoju, gẹgẹbi zirconium ati tin.

Atẹgun, nitrogen, erogba ati hydrogen jẹ awọn idoti akọkọ ni awọn ohun elo titanium.Solubility ti atẹgun ati nitrogen ni ipele α tobi julọ, eyiti o ni ipa agbara pataki lori alloy titanium, ṣugbọn o dinku ṣiṣu.Awọn akoonu ti atẹgun ati nitrogen ni titanium nigbagbogbo wa ni isalẹ 0.15 ~ 0.2% ati 0.04 ~ 0.05%, lẹsẹsẹ.Hydrogen ni o ni solubility pupọ diẹ ninu ipele α, ati pe hydrogen pupọ ti tuka ninu awọn ohun elo titanium n ṣe awọn hydrides, eyiti o jẹ ki alloy brittle.Akoonu hydrogen ni alloy titanium ni a maa n ṣakoso ni isalẹ 0.015%.Ituka hydrogen ni titanium jẹ iyipada ati pe o le yọkuro nipasẹ annealing igbale.

Kemikali Tiwqn

| Ipele | N | C | H | Fe | O | Al | V | Pa | Mo | Ni | Ti |

| Gr1 | 0.03 | 0.08 | 0.015 | 0.2 | 0.18 | / | / | / | / | / | Bal |

| Gr2 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | / | / | Bal |

| Gr3 | 0.05 | 0.08 | 0.015 | 0.3 | 0.35 | / | / | / | / | / | Bal |

| Gr4 | 0.05 | 0.08 | 0.015 | 0.5 | 0.4 | / | / | / | / | / | Bal |

| Gr5 | 0.05 | 0.08 | 0.015 | 0.4 | 0.2 | 5.5-6.75 | 3.5-4.5 | / | / | / | Bal |

| Gr7 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | 0.12-0.25 | / | / | Bal |

| Gr9 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 | 2.5-3.5 | 2.0-3.0 | / | / | / | Bal |

| Gr12 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | 0.2-0.4 | 0.6-0.9 | Bal |

Agbara fifẹ

| Ipele | Ilọsiwaju(%) | Agbara Fifẹ (Min) | Agbara ikore (Min) | ||

| ksi | Mpa | ksi | Mpa | ||

| Gr1 | 24 | 35 | 240 | 20 | 138 |

| Gr2 | 20 | 50 | 345 | 40 | 275 |

| Gr3 | 18 | 65 | 450 | 55 | 380 |

| Gr4 | 15 | 80 | 550 | 70 | 483 |

| Gr5 | 10 | 130 | 895 | 120 | 828 |

| Gr7 | 20 | 50 | 345 | 40 | 275 |

| Gr9 | 15 | 90 | 620 | 70 | 438 |

| Gr12 | 18 | 70 | 438 | 50 | 345 |

Titanium Ati Alloy Products

| Orukọ ọja | Awọn pato |

| Titanium Rod & Pẹpẹ & Ingots | Ф3mm ~ Ф1020mm, iwuwo ti o pọju jẹ to 12t |

| Titanium pẹlẹbẹ | (80~400)mm×(~1500)mm×(~2600)mm |

| Titanium Forgings | Iwuwo fun nkan≤2000kg |

| Titanium Gbona-yiyi farahan | (4~100)mm×(800~2600)mm×(2000~12000)mm |

| Titanium Tutu-yiyi Sheet | (0.01~4.0)mm×(800~1560)mm×( ~6000) mm |

| Titanium Bankanje / awọn ila | (0.01~2.0)mm×(800~1560)mm×L |

| Titanium Falopiani / paipu | Ф(3~114)mm×( 0.2~5)mm × (~15000)mm |

| Awọn ajohunše | GB,GJB,ASTM,AMS,BS,DIN,DMS,JIS,ГОСт |

| Titanium ite |

|

Ifihan ọja