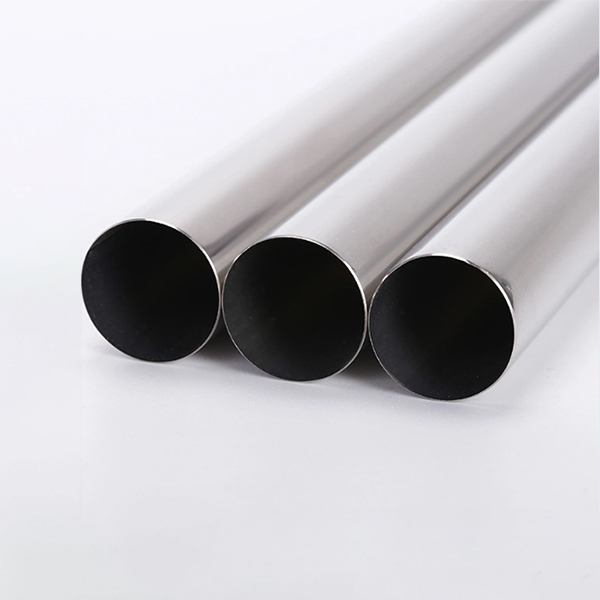

TA2 titanium alloy tube fun lilo ile-iṣẹ

TA2 Titanium Alloy Pipe, Awọn anfani

TA2 Titanium Alloy Pipe, Ti a ṣe afiwe pẹlu awọn ohun elo irin miiran, o ni awọn anfani wọnyi:

1. Agbara ti o ga julọ (agbara fifẹ / iwuwo) (wo nọmba), agbara fifẹ le de ọdọ 100 ~ 140kgf / mm2, nigba ti iwuwo jẹ 60% nikan ti irin.

2. Agbara iwọn otutu alabọde dara, iwọn otutu lilo jẹ ọpọlọpọ awọn iwọn ọgọrun ti o ga ju alloy aluminiomu, ni iwọn otutu alabọde le tun ṣetọju agbara ti a beere, le ṣiṣẹ ni iwọn otutu 450 ~ 500 ℃ fun igba pipẹ.

3. Ti o dara ipata resistance, titanium dada ni awọn bugbamu ti lẹsẹkẹsẹ akoso kan Layer ti aṣọ ile ati ipon ohun elo afẹfẹ fiimu, ni o ni agbara lati koju a orisirisi ti media ogbara.Titanium ni gbogbogbo ni aabo ipata to dara ni oxidizing ati media didoju, pataki ni omi okun, chlorine tutu ati awọn ojutu kiloraidi.Ṣugbọn ni idinku alabọde, gẹgẹbi ojutu hydrochloric acid, titanium ipata resistance ko dara.

4. Titanium alloys pẹlu iṣẹ otutu kekere ti o dara ati awọn eroja imukuro kekere pupọ, gẹgẹbi TA7, le ṣetọju ṣiṣu kan ni -253 ℃.

5. Irẹwẹsi rirọ kekere, iwọn ina gbigbona kekere, ko si feromagnetism.

6. Lile giga.

7. Ko dara stamping ohun ini ati ki o dara thermoplasticity.

Ooru itọju Titanium alloy le gba o yatọ si alakoso tiwqn ati microstructure nipa Siṣàtúnṣe iwọn otutu ilana.O ti wa ni gbogbo ka pe itanran equiaxed microstructure ni o dara plasticity, gbona iduroṣinṣin ati rirẹ agbara.Eto acicular ni agbara ti o tọ ti o ga julọ, agbara irako ati lile lile fifọ.Equiaxed ati acicular adalu ẹya ni dara okeerẹ-ini.

TA2 Titanium Alloy Pipe, Awọn ọna itọju ooru ti a lo nigbagbogbo jẹ annealing, ojutu ati itọju ti ogbo.Annealing ni lati yọkuro aapọn inu, ilọsiwaju ṣiṣu ati iduroṣinṣin microstructure, lati le gba awọn ohun-ini okeerẹ to dara julọ.Ni gbogbogbo, iwọn otutu annealing ti α alloy ati (α+β) alloy jẹ 120 ~ 200℃ ni isalẹ aaye iyipada ti (α+β) -- → β alakoso.Ojutu ati itọju ti ogbo ni lati gba ipele α ati ipele metastable β ti martensite nipasẹ itutu agbaiye yara ni agbegbe iwọn otutu ti o ga, ati lẹhinna decompose awọn ipele metastable wọnyi nipa didimu ni agbegbe iwọn otutu aarin, ati gba awọn patikulu alakoso keji ti o tuka daradara. , gẹgẹ bi α alakoso tabi yellow, lati se aseyori awọn idi ti okun alloy.Nigbagbogbo (alpha + beta) alloy quenching ni alpha + beta) --> aaye iyipada ipele ipele ni isalẹ 40 ~ 100 ℃, quenching beta alloy metastable ni alpha + beta) -- -> aaye iyipada ipele ipele beta loke 40 ~ 80 ℃.Ni gbogbogbo, iwọn otutu ti ogbo jẹ 450 ~ 550 ℃.Ni afikun, lati le pade awọn ibeere pataki ti iṣẹ-ṣiṣe, ile-iṣẹ naa tun nlo annealing meji, isothermal annealing, itọju ooru β, itọju ooru abuku ati ilana itọju ooru irin miiran.

TA2 Titanium Alloy Pipe, Classification

Titanium pipe, titanium alurinmorin pipe, titanium splicing tee, titanium splicing igbonwo, titanium alurinmorin oruka, titanium atehinwa, titanium tee, titanium igbonwo, titanium simini, ati be be lo.

TA2 Titanium Alloy Pipe, Ilana Ṣiṣẹ Ti

TA2 Titanium Alloy Pipe, Ni akọkọ sisopọ gbogbo iru opo gigun ti epo ohun elo titanium, ti a lo fun kaakiri ohun elo laarin gbogbo iru ohun elo, opo gigun ti epo ni resistance ipata ti ohun elo titanium funrararẹ, nitorinaa lati rọpo opo gigun ti epo gbogbogbo fun opo gigun ti arinrin ko le pade ibeere naa. .Ni gbogbogbo ф 108 loke ti wa ni welded oniho.

Main Technical Parameters

| DN (mm) | Wiwọn opin ita (mm) | Awọn ohun elo |

| 15 | 18 | TA2 |

| 20 | 25 | TA2 |

| 25 | 32 | TA2 |

| 32 | 38 | TA2 |

| 40 | 45 | TA2 |

| 50 | 57 | TA2 |

| 65 | 76 | TA2 |

| 80 | 89 | TA2 |

| 100 | 108 | TA2 |

| 125 | 133 | TA2 |

| 150 | 159 | TA2 |

| 200 | 219 | TA2 |

| 250 | 273 | TA2 |

| 300 | 325 | TA2 |

| 350 | 377 | TA2 |

| 400 | 426 | TA2 |

| 450 | 480 | TA2 |

| 500 | 530 | TA2 |

| 600 | 630 | TA2 |

Ifihan ọja